Introduction: A Harsh Landscape, a High-Stakes Mission

Introduction: A Harsh Landscape, a High-Stakes Mission

Algeria’s upstream sector is undergoing a resurgence. As Sonatrach expands exploration in the Hassi Messaoud, Berkine, and Illizi basins, operators are facing a unique convergence of challenges: high-pressure, high-temperature (HPHT) wells; abrasive sandstone formations; and remote, arid desert conditions. In this demanding environment, reliability is non-negotiable—and customization is key.

Parveen Industries supports Algeria’s upstream ambitions with a robust line of custom-engineered downhole tools and surface systems, designed specifically for HPHT, desert, and remote-field performance.

Algeria’s HPHT Reality

Shale-like reservoirs in Algeria often present:

- Bottomhole pressures >10,000 psi

- Temperatures exceeding upto 300°F.

- Abrasive formations requiring specialized completions

- Limited access and extreme weather in the Sahara

These factors demand a specialized approach:

- High-grade metallurgy

- Heat-resistant elastomers

- Modular tool design for remote rig transport

- API 6A and ISO 14310 certification

Downhole Tools Built for Sahara Conditions

1. Bridge Plug

Our bridge plugs are constructed for high anchoring force and high-temp sealing.

- Available in retrievable and drillable versions

- HPHT rated for extreme pressure differential

- Proven in deep gas wells across Hassi Berkine

2. Cementing Equipment

Reliable cementing equipment is vital for zonal integrity.

- High-density float shoes and centralizers

- Multi-stage systems for long vertical wells

- Compatible with coil tubing cementing

3. Production Packer

Our production packers offer permanent and retrievable options.

- Elastomers rated to 300°F

- NACE MR0175 certified for H2S environments

- High-slip anchoring for unstable Sahara formations

Coil Tubing & Pressure Control

4. Coil Tubing Equipment

Our coil tubing tools are designed for cleanout, stimulation, and scale removal.

- Abrasion-resistant nozzles

- Hydraulic disconnects

- Customized for high-rate gas wells

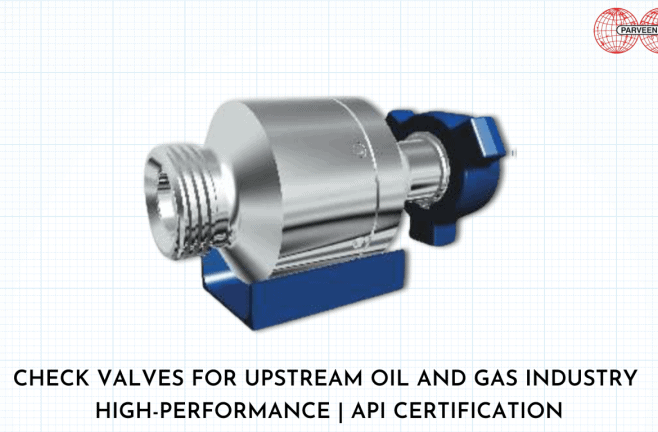

5. Equalizing Valve & Plug Valve

Our equalizing valves balance pressure across zones safely, while Plug Valves deliver zero-leak performance in production and testing operations.

Surface Systems for Harsh Climates

6. API 6A Gate Valve & Wellhead Equipment

We offer API 6A gate valves and wellhead & Xmas tree assemblies built to handle HPHT load cycles and corrosive fluids.

- PSL 3G qualified

- Anti-sand erosion internals

- Hydraulic actuator compatibility

7. Wellhead Parts & Custom Assemblies

All wellhead equipment is engineered and stocked in modular kits to reduce on-site integration delays. We provide comprehensive spare kits for Algerian field maintenance teams.

Debris Management & Flow Assurance

8. Casing Scraper & Non-Rotating Scraper

Our casing scrapers clean cement, scale, and debris before completions, while non-rotating casing scrapers protect deviated wellbores from torsional damage.

9. Gravel Pack Equipment

Unconsolidated sandstone in Algeria demands effective sand control. Our gravel pack equipment features custom screen gauges and crossover tools to maintain production integrity.

Production Testing Packages for Desert Deployment

Our production testing equipment is built for portability and modularity.

- Skid-mounted designs for desert logistics

- Quick-connect manifolds for faster setup

- API 12K separators, 2/3-phase designs, and surge tanks

FAQs

Can tools be shipped to remote desert fields?

Absolutely. All systems are modular and shipped in field-ready crates with rapid deployment guides.

Are your equipment and spares available in-country?

We maintain stock availability through regional distribution channels and supply partners.

Conclusion: Engineered for the Sahara, Trusted by Operators

Conclusion: Engineered for the Sahara, Trusted by Operators

From scorching heat to unpredictable formations, Algeria’s Sahara Basin presents one of the most unforgiving environments in oil & gas. Parveen Industries equips operators with custom downhole tools and surface systems that go beyond API compliance—they are built for resilience, speed, and zonal control.

When it comes to Algeria’s HPHT challenges, performance isn’t optional. It’s engineered.