DESCRIPTION

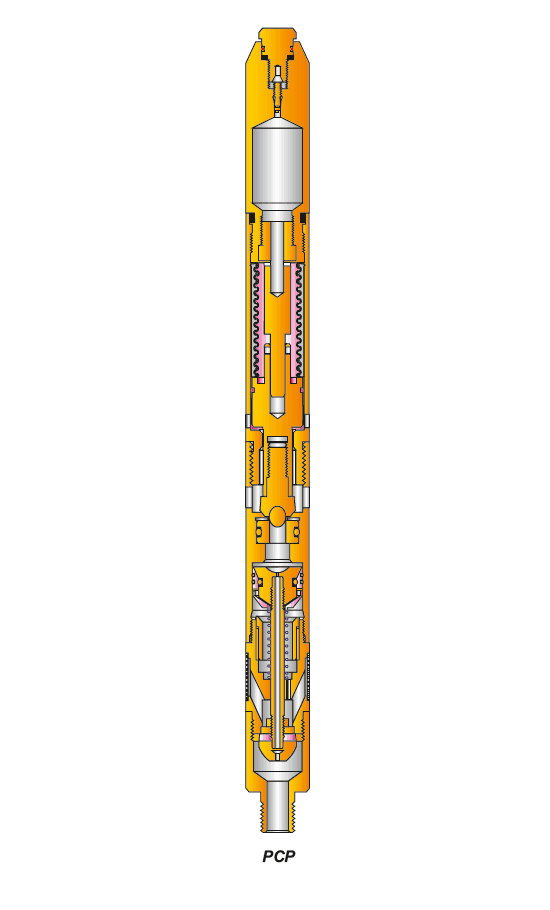

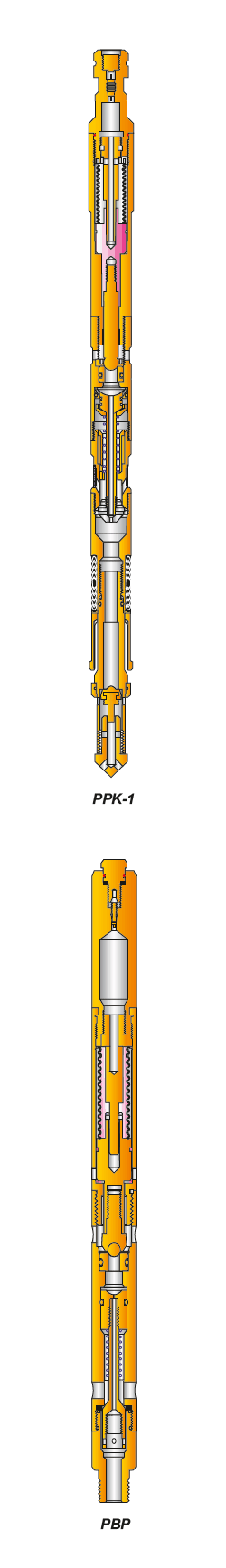

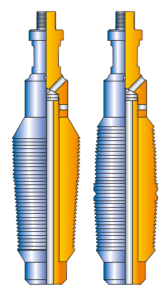

The PARVEEN Conventional Pilot Valve (1″ & 1.1/2″O.D) and Retrievable Pilot Valve ( 1″ O.D. ) consists of a pilot section and a power section. This valve utilizes a pilot section to activate a power section. A sealed chamber, including a multiply monel bellow, contain a nitrogen pressure charge over a dampening fluid which provides the closing force necessary to maintain the pilot section in a normally closed position and an inconel spring provides the force necessary to maintain the power section normally in a closed position.

OPERATION

Injection gas first enters the pilot section of the valve and acts on the effective bellows area. When injection gas pressure exceeds the closing force (due to precharged nitrogen gas pressure in the bellows), the bellow compresses, lifting the pilot valve stem off the seat to open the pilot section and thus allows gas to be injected on top of the power piston. The differential between injection gas pressure and production fluid pressure, working on the annulus area between the power piston and port areas overcomes the spring closing force of the power section piston. This differential pressure opens the power section, allows injection gas to flow through the valve, past the reverse flow check valve into the production fluid through the production conduit. When pilot section closes due to injection gas pressure drop, the injection gas pressure on top of the power piston bleeds down to production fluid pressure and the spring closes the power section.

APPLICATION

Pilot operated valves are used primarily for intermittent gas lift where large, instantaneous injection gas volumes between opening and closing injection gas pressure are desired. The pilot valve can also be used where intermittent lift is required but injection gas must be controlled by a choke to prevent surface gas system pressure fluctuations.

ENGINEERING DATA FOR RETRIEVABLE PILOT OPERATED GAS LIFT VALVE.