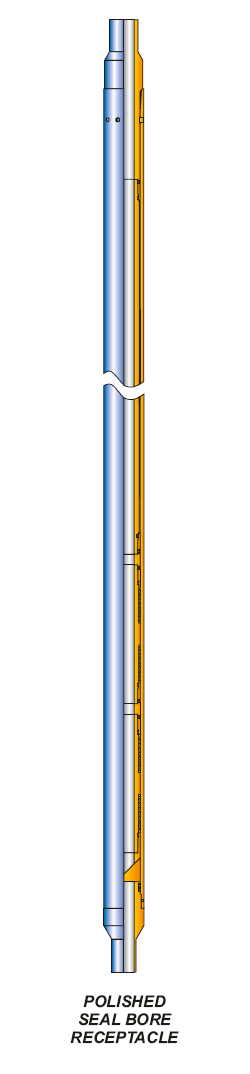

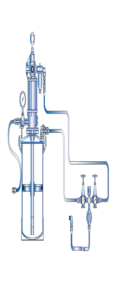

The PARVEEN Polished Seal Bore Receptacle is designed for applications where a large ID mustbe maintained through the completion while accommodating extreme tubing movements. ThePARVEEN Polished Seal Bore Receptacle modular design allows tool to be easily converted fromtension release to hydraulic release. The tension release and the hydraulic release incorporate aPolished Seal Bore Receptacle as well as a PBR seal assembly including 2 sets of working sealunits and a debris barrier above and below the working seals. Both versions when combined witha hydraulic or hydraulic/ hydrostatic set can be run in and set in one trip. The polished seal borereceptacle can be retrieved in two trips. The seal assembly is retrieved when the tubing string isrecovered. The PBR seal bore is retrieved with a PBR retrieving tool. The Polished Seal BoreReceptacle is available in varying lengths of up to 25 ft. in stroke. An adjustable shear mechanismlocks the outer housing and seal mandrel together during run-in. Once the seal assembly isreleased, it is free to move in the bore, compensating for tubing movement. The PBR assemblycan be pinned in the fully stroked, closed or midway position to accommodate pre-spacing in onetrip completions.

Features:

- One-piece polished bore housing

- Full bore-seal mandrel allows passage of intervention tools

- Adjustable shear-release mechanism

- Available with premium materials and connections

- Available in stroke lengths up to 25 ft.

- Metal-to-metal connections for hostile environments

- Debris barrier above and below seals for long life

- Seals are retrieved on the tubing string

- Threaded receptacle on top for PBR retrieval on workstring

Benefits:

- Maximum-flow capability

- Retrieves separately from the packer, simplifying removal

- Rugged design for rotating into liner tops and horizontal sections

- No tubing manipulation required to set

- Reduces installation time

- Can be pinned in the fully stroked, closed or midway position

- CRA materials available for hostile environments

Applications:

- One-trip installations in deviated or horizontal wells

- Large-bore, high-flow-rate applications

- Production, injection, or stimulation

- Monobore completions