Market Introduction

In the oil and gas industry, the choke and kill manifolds are used in controlling well kick and pressure fluctuations. These necessary pieces of oilfield equipment are used to prevent well-bore influx or kick and to manage well pressure fluctuations which often happen during drilling.

Ever-growing demand for energy is one of the major factors driving the global drilling activities and the demand for oil and gas equipment. Growing consumption of oil and gas products is one of the major drivers of the choke and kill manifold market. Owing to major public safety and environmental concerns and hence obvious stringent government regulations resulting in imposition of hefty penalties on the oil and gas companies has resulted in a surge in demand for pressure control equipment and thus chokes and kill manifold systems. Furthermore, growing exploration and production activities and increase in the rig count globally is fueling the growth of the choke and kill manifold market. Increasing expenditure on the setup of pressure control equipment by oil and gas companies and growing drilling contracts is also triggering the choke and kill manifold market growth.

Market Dynamics

According to one of the recently published market research report by Technavio, the global choke and kill manifold market is expected to post a CAGR of approximately 8% during the period 2019-2023.

Choke and kill manifolds manage well pressure fluctuations during drilling by diverting flow through valves and chokes, thus necessitating the use of choke and kill manifold which is propelling the growth of the choke and kill manifold market. Moreover, the growing oil and gas industry is raising demand for the pressure control equipment that are augmenting the growth of the choke and kill manifold market. The increasing demand for energy across the globe is growing drilling activities that are expected to drive the growth of the choke and kill manifold market.

Market Segmentation & Regional Framework

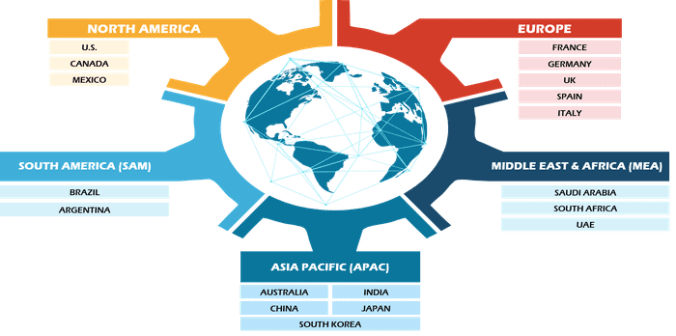

The global choke and kill manifold market is segmented on the basis of application as onshore, offshore; and as per geography (APAC, Europe, MEA, South America, and North America).The demand for the choke and kill manifolds are more in offshore drilling activities where there is a need for pressure control equipment.

“The rise in crude oil prices has led to an increase in drilling and production operations in offshore deepwater and ultra-deepwater drilling projects. The drilling activities at such depths require rugged equipment which can handle the high pressure. This is expected to support the growth of the global choke and kill manifold market,” says a senior research analyst at Technavio.

Learn more about choke and kill manifolds here.

The choke and kill manifolds are among the necessary pieces of equipment needed in oil and gas production. While many people might have already heard about choke and kill manifolds, only a few fully understand what they really are. Read on to know more about what choke and kill manifolds are, as well as their uses and significance in the oil and gas industry.

What Is Choke & Kill Manifold?

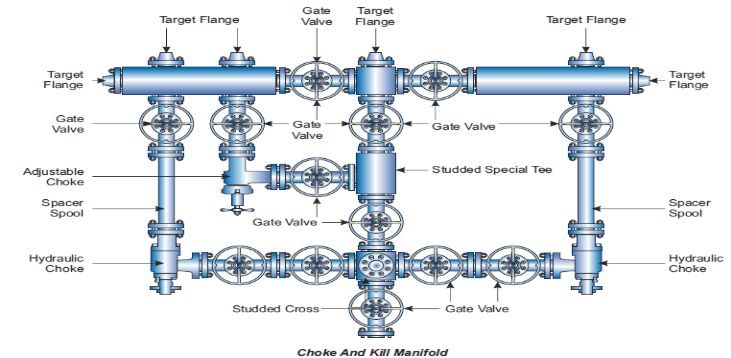

A choke manifold is an assembly of piping and valves with adjustable choke valves. This arrangement is mainly responsible for controlling flows and pressures during the onshore and offshore well testing and production operations. By installing a choke manifold, the operators can manage the speed of flow and pressure that enter the processing equipment, which helps in controlling production and reduces the risk of equipment damage. During well test wellheads are attached to the choke manifold to control pressure and allow flow for the test components downstream.

Choke & kill manifolds are primarily used in the oil and gas industry, but they are also used in the trenchless industry for drilling operations that employ drilling mud (also known as drilling fluid).

There is also another application of the manifold, which is used to bring down the pressure, which is encountered from the wellhead. This consists of a set of high-pressure valves with two minimum numbers of chokes. This choke comes in adjustable or fixed design or maybe both. This redundancy is required when one of the chokes is out of service, and the flow is to be directed with another choke to avoid downtime in production. The choke valve consists of a set of outer board valves and inboard valves with flanges, pressure gauge, hydraulic and manual chokes.

The primary feature of the choke manifold is to control the pressures of the drilling fluid ejected at the cutting head. Mainly during recirculation, when the mud is circulated through the choke manifold when the blowout preventer is closed.

During well testing, choke manifolds allow flows and pressures to be controlled. Choke & kill manifolds typically consist of more than one choke valve. If one choke valve on the manifold fails or has to be taken out of service, fluid flows can be redirected to the other valves.

What are the primary Manifold System Components?

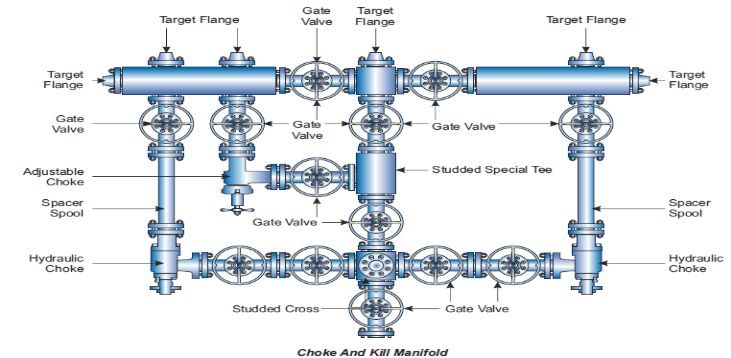

Chokes

Parveen’s chokes are manufactured to API 6A suitable for fixed as well as variable flow, with wide choice of temperature ratings and end connections (API/ANSI, Flanged/Threaded) to meet a variety of services. Sizes available from 2.1/16” 2k to 3.1/16 15k. The choke manifold is primarily an assembly of choke valves. These valves are designed in a way to restrict the flow when required. By adjusting the valves, the flow can be easily regulated. Adjustable choke valves typically come with a manual or automatic valve stem and are more common because of their flexibility.

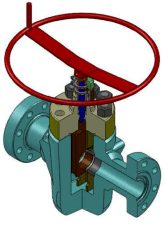

Gate valve

Generally, the gate valve is used in manifolds because of its high resistance to wear and sufficient seal. They are designed to control the fluid flow from opening to closing, but they are not explicitly designed to restrict the flow. If the gate valve is limiting the flow, it can damage the body due to its abrasive characteristic of the fluid, which is considered as solid laden fluid. Also, the damage can occur on the valve during downstream due to high velocity as it goes through the choke section and increases the chance of erosion.

Primary functions of Choke and Kill Manifold:

- The primary function of a choke & kill manifold is to improve the overall process safety around the site. In the oil and gas industry, it is used to control the pressures of the drilling fluid ejected at the cutting head. The assembly of choke valves which are the most important element of the manifold is specially engineered to restrict flow as required. The flow is restricted or regulated by adjusting the valves.

- Maintain flow rates required for testing. Different tests may require different flow rates over various time periods. There are also some tests that would require the flow rates to be changed over a specified time frame. The choke and kill manifold can help the operator effectively control these flow rates according to the test requirements.

- In certain applications, the choke manifold may used to prevent or minimize the quantity of sand, debris and other materials from entering the well. This can be done by reducing the flow speed and flow rate.

- Apart from the oil and gas industry, the choke and kill manifolds are also used in the trenchless industry and in applications that involve drilling that includes the use of drilling fluid or drilling mud. They are also used in industrial operations like offshore and onshore well testing and production operations.

- The manifold ensures that pressure fluctuations downstream of the manifold do not affect the downhole pressure and flow rate at the well.

PARVEEN fabricates custom designed Manifolds:

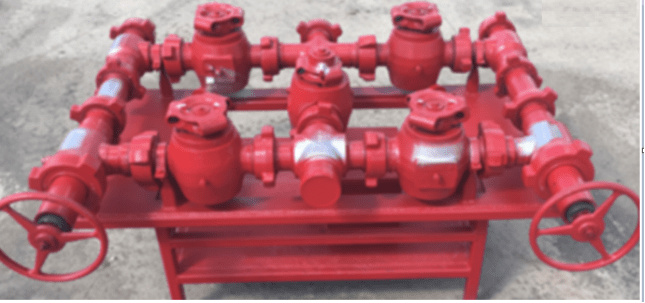

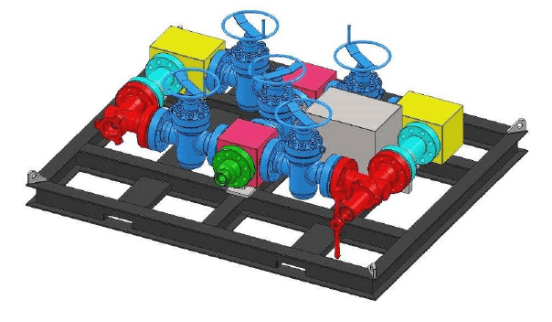

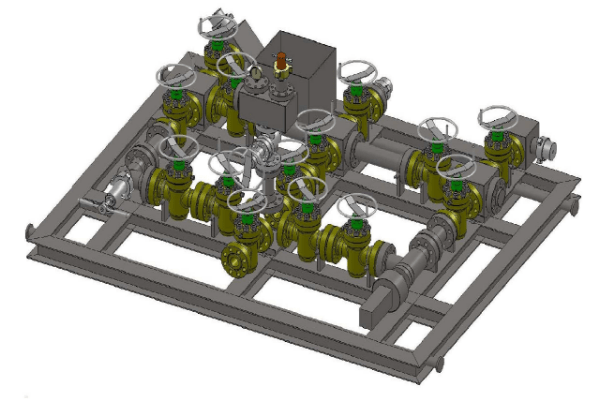

Parveen Industries is India’s leading manufacturer of choke and kill manifolds used in the oil and gas industry. The company designs and fabricates choke and kill manifolds in sizes 2” to 4” and up to 15,000 PSI for standard and sour services. Apart from the standard choke and kill manifold designs, Parveen offers custom-made manifolds.

Parveen’s choke & kill manifold systems may incorporate API 6A monogrammed gate valves, check valves, plug valves, chokes and actuators depending upon the application. The custom designs are specially created and fabricated to ensure they met your requirements. Other types of Manifold (Standpipe manifold, Cementing manifold, Custom manifold etc.) can also be made available.

Parveen offers PSL-2 (or better) and PR-1 (or better) choke and kill manifolds with material class DD-NL, a temperature rating U, hard-faced seats and gates, alloy 625/ SS 316 inlaid ring grooves and hydraulic actuation for remote operation. Parveen can also customize the choke and kill manifold according to your chosen specifications, materials, and component to ensure it perfectly fits your needs.

Whether you need a new set of manifolds or you want to replace your worn-out, broken, or inefficient oilfield equipment to extend the life of your entire system, you can trust Parveen Industries to meet your requirement. The company also offers sour services for various applications including choke manifold for flow back or workover, well treatment or stimulation services, production manifold for diverting flow-through test separator, and gas manifold for gas diversion through the burner or orifice meter.

Parveen’s Choke manifold specifications |

|

| API Size | 2.1/16″ to 4.1/16″ |

| Material Grade | DD-NL |

| Working pressures | 5,000 psi to 150,000 psi |

| Temperature class | U (0 to 250°F) |

| Products specification level | PSL2, PSL3, PSL3G, PSL4 |

| Service Condition | Standard/Sour/NACE MR0175 |

| API standards | API 6A |

| Manufacturing certification | ISO 9001 |

| Special requirement | SS316 / Inconel® 625 inlay available |

Types of Manifold:

1. Choke Bean

This type of choke comes under the fixed choke category, which is used to control the fluid flow. This choke is designed in such a manner that Bean is replaceable in future. It is made up of hardened steel. Choke Bean is mounted near the X-MAS tree- either it can be single completion or dual completion, with a set of valves and fitting at the top of well controlled production or flow, which comes with the latest standard of API-6A—provided by Parveen Industries Pvt. Ltd. This choke bean is so precisely manufactured to the choke diameter which provides seamless fluid flow through it. The diameter of the choke bean is available in different sizes and is identified by choke diameter.

In a choke bean, without depending upon the position, Choke bean can create back pressure on the well. Hence it results in high pressure on the bottom of the well. It is often used as a positive choke valve to control the flow.

2. Franc Manifold

It is used for directing treatment fluid.

3. Squeeze Manifold

It is used for squeezing cementing work.

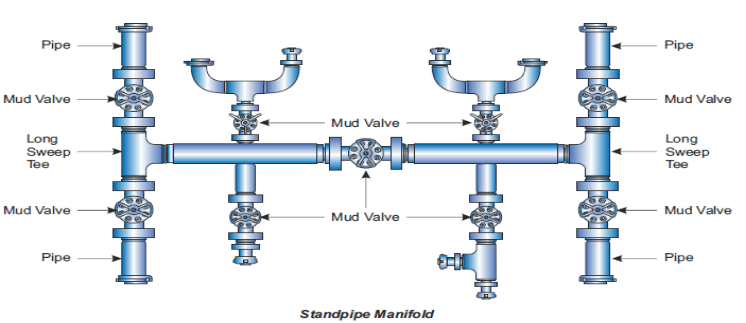

4. Mud Standpipe Manifold

Mud Standpipe Manifold is fitted downstream for diverting the flow pressure of drilling fluids towards drill line or drill string. The equipment can take pressure up to 7,500 PSI using standard mud valves. All the Welded, Flanged, hubbed or hammer union connections are available. Mud Standpipe can be designed as per the requirements of the customers.

Specifications:

PSL-2 (or better) (7,500 PSI and lower) or customer to specify.

PR-1 (or better) or customer to specify.

Material: DD-NL (or better) or customer to specify.

Temperature Rating `U’ (7,000 PSI working pressure or lower) or customer to specify.

Alloy 625/ SS 316 Inlaid Ring Grooves or Customer to Specify.

Range of configurations, capacities & specifications.

Custom single or dual designs.

Hammer union, flange or hub connection.

Gates and seats shall be hard-faced.

For Well Testing / Completion / Intervention, industry uses varies configuration of Manifold, as per requirement of Service / Operating Companies.

Specifications:

PSL-2 (or better) or customer to specify.

PR-1 (or better) or customer to specify.

Material: DD-NL (or better) or customer to specify

Temperature Rating `U’ or customer to specify.

Alloy 625/ SS 316 Inlaid Ring Grooves or Customer to Specify.

Gates and seats shall be hard-faced.

Hydraulic actuated for remote operation.

Recertification available at Parveen’s facility.

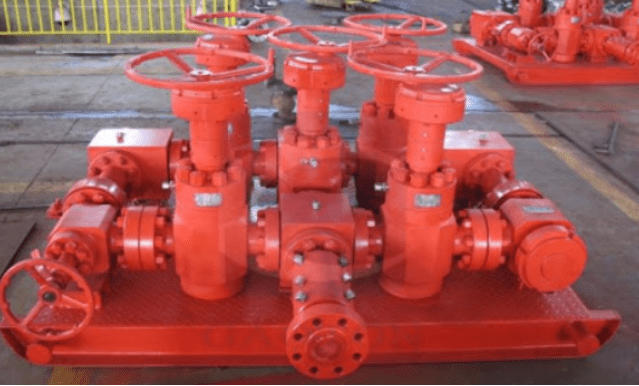

Choke & Kill Manifold with Plug valves

Choke & Kill Manifold with Gate valves

Choke & Kill Manifolds engineered to make for our valuable customer

About Us

Parveen Industries Pvt. Ltd is India’s one of the leading manufacturer of oilfield equipment for oil and gas industry. The company builds all the equipment using cutting-edge technology and high-quality materials that are reliable as well as durable.