Introduction:

Parveen Industries Pvt. Ltd is India’s one of the leading manufacturer of oilfield equipment for oil and gas industry. The company builds all the equipment using cutting-edge technology and high-quality materials that are reliable as well as durable.

Parveen is specialized in design and supply of Completion tools like Production packers Bridge plugs and their accessories by using the well established quality management system that meets API and ISO standards.

Our Focus is to provide efficacious solutions and deliver products with durability and quality. We encourage excellent workmanship in our product line with the best knowledge in the Oil and Gas upstream Industry.

We, employ engineers, designers and technical support staff with huge experience, having background of mechanical and petroleum engineering to design and manufacture completion tools.

All About Packers:

Packer is a mechanical device with a packing element installed in a designed receptacle, used for blocking fluid (liquid or gas) communication through the annular space between conduits by sealing off the space between them”.

A Packer is usually set just above the producing zone to isolate the producing interval from the casing annulus or from producing zones elsewhere in the wellbore.

In cased hole completions, production casing is run along the entire length of the well and through the reservoir. The cased hole effectively acts as a control mechanism for safe production of desired hydrocarbons and as a barrier preventing the reintroduction of unwanted fluids, gases, and solids into the wellbore.

After the drill string has been removed, a continuous coupling of casings of different diameters is run into the well at varying depths and secured to the formation in a process known as Cementing. ‘Cement’ here refers to a mixture of cement and certain additives which is pumped into the well and fills the vacuum between the casing and surrounding formation.

After the wellbore has been completely insulated from the surrounding formation, the casing must be perforated to stimulate production from viable sections of the reservoir called ‘pay zones’. Perforation is performed using ‘Perforating guns’ which set off controlled explosions that blast holes through specific sections of the casing (and into the reservoir) for controlled production of hydrocarbons.

Parveen offers a complete line of production packers and accessories — from standard packers to specialized designs for the most hostile environments. Our packers are designed as per API 11 D1 Validation Grade V6-V0 and Quality Control Grade Q3-Q1.

Functions of Packer:

In addition to providing a seal between the tubing and casing, other functions of a packer are as follows:

Prevent downhole movement of the tubing string, generating considerable axial tension or compression loads on the tubing string.

Support some of the weight of the tubing where there is significant compressive load on the tubing string.

Allows the optimum size of well flow conduit (the tubing string) to meet the designed production or injection flow rates.

Protect the production casing (inner casing string) from corrosion from produced fluids and high pressures.

Can provide a means of separating multiple producing zones.

Hold well-servicing fluid (kill fluids, packer fluids) in the casing annulus.

Facilitate artificial lift, such as continuous gas lifting through the A-annulus.

Packer’s Key Components:

Body or mandrel:

Mandrel is a main component of a packer that contains the end connections and provides a conduit through the packer. It is subjected to direct exposure to flowing fluid hence its material selection is a very vital decision. Primarily used materials are L80 Type 1, 9CR, 13CR, 9CR1Mo. For more corrosive and sour services Duplex, Super Duplex, Inconel are also used as per the requirement.

Slips:

The slip is a wedge-shaped device with wickers (or teeth) on its face, which penetrate and grip the casing wall when the packer is set. There are different types of slips designs are available in packers like dovetail slips, rocker type slips bidirectional slips depending upon packer assembly requirements.

Cone:

The cone is beveled to match the back of the slip and forms a ramp that drives the slip outward and into the casing wall when setting force is applied to the packer.

Packing-element system

Packing element is the most important part of any packer and it provides the primary sealing purpose. Once the slips have anchored into the casing wall, additional applied setting force energizes the packing-element system and creates a seal between the packer body and the inside diameter of the casing. The primarily used element materials are NBR, HNBR or HSN, Viton, AFLAS, EPDM etc. Most popular element system are permanent single element system with expansion ring, three piece element system with spacer ring, ECNER element system, Spring loaded element system, Fold back ring element system.

Lock ring:

Lock ring play a vital role in packer’s function. The purpose of a lock ring is to transmit axial loads and allow unidirectional motion of packer components. The lock ring is installed into the lock ring housing and both move together over the lock ring mandrel. All setting force generated due to tubing pressure is locked into packer by lock ring.

Packer Types:

Production packers can be classified into two groups:

Permanent

Retrievable

Permanent Packers

As the name implies Permanent Packers cannot be retrieved, but can be destructively removed (i.e. milling).The permanent packer is fairly simple and generally offers higher performance in both temperature and pressure ratings. In most instances, it has a smaller outside diameter (OD), offering greater running clearance inside the casing string than do retrievable packers. The smaller OD and the compact design of the permanent packer help the tool negotiate through tight spots and deviations in the wellbore. The permanent packer also offers the largest inside diameter (ID) to make it compatible with larger-diameter tubing strings and monobore completions.

Permanent packers are further categorized in two types:

Hydraulic Set

Wireline Set

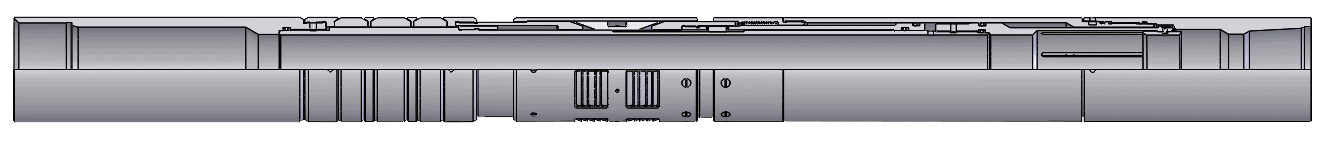

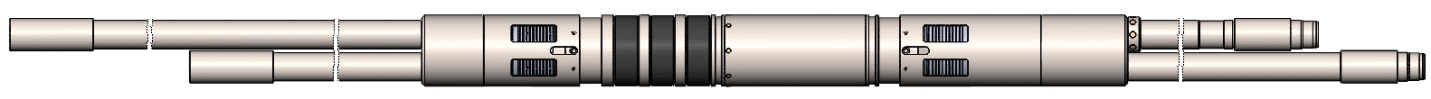

PARVEEN’S Model ‘D’ & ‘F’ Production Packers are available to fit your needs and provide the versatility of our excellent pack-off system for a positive secure set in the well bore. These packers assist in the economical operation of a variety of completion and production jobs. These are designed to accommodate seal bore extensions used in deep wells requiring a longer seal bore interval. Seal Nipples are available with either automatic square-thread latch or locating shoulder. These packers can be used as test tools. Full opening bores allow the passage of perforating guns used to perforate a zone below for testing. If the zone proves to be non-productive, the packer can be used as a squeeze tool. These packers are wire line set packer.

PARVEEN Model D Production Packers provide excellent clearance for run-in while the PARVEEN Model “F” Production Packers offer a larger seal bore. The two models carry different pressure ratings noted later in this document. PARVEEN Packers are designed for differential pressures up to 10,000 PSI.

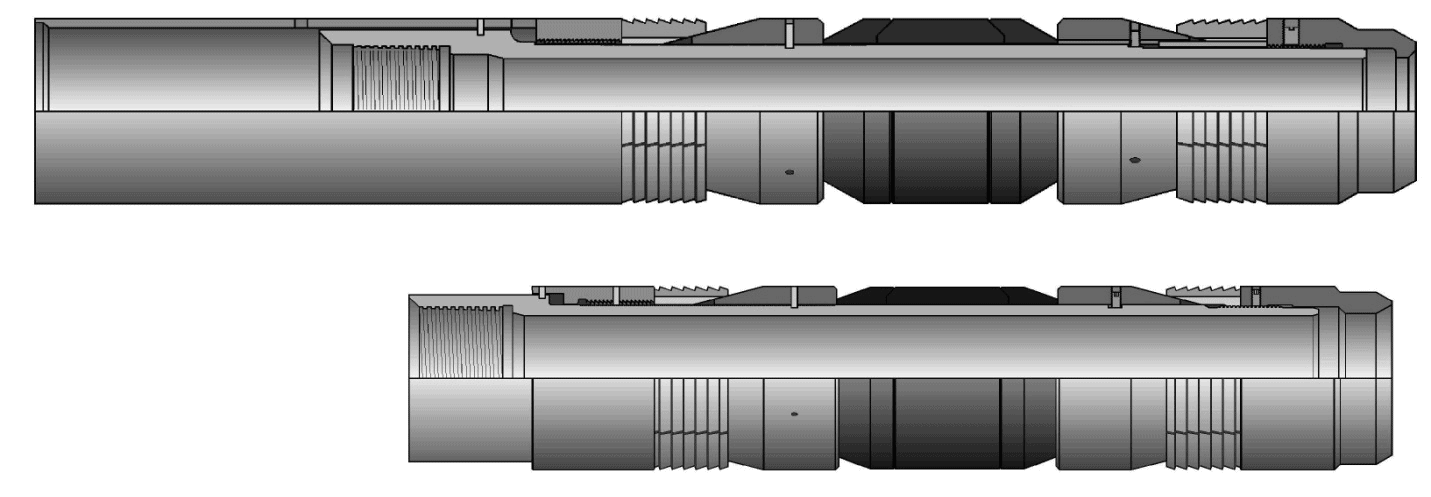

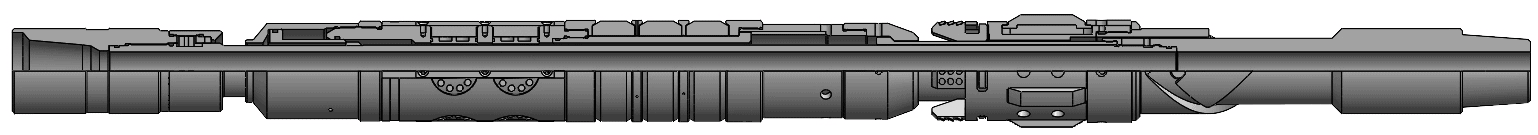

MODEL D & F PERMANENT PACKER

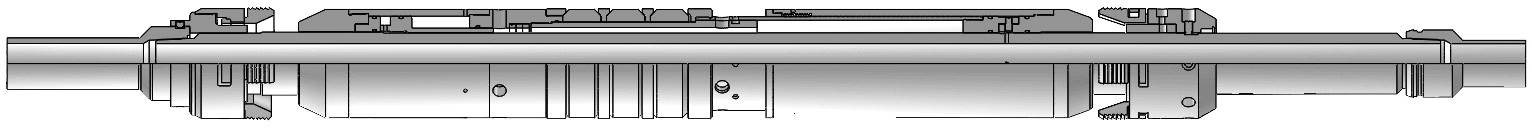

PARVEEN Model DB Hydraulic-Set Dual Bore Permanent Production Packers are the hydraulically set one-trip completion packers, ideal for high volume production in high angle, extremely deviated well. These packers feature the largest possible bore through combined packer and seal accessory. The packer is run on the hydro-set anchor latch seal unit which is made up in the top of the packer via the left-hand threads on the latch and is set by applied tubing pressure. The DB packer requires some type of temporary plugging device such as a shear out plug or wire line blanking plug located close to the end of the tubing. PARVEEN Packers are designed for differential pressures up to 10,000 PSI.

MODEL DB PERMANENT PACKER

Retrievable Packers

Retrievable Packer has a design feature that enables its removal from the well posts operation or whenever required. This packer can be retrieve with tension in tubing or with retrieving tool. Parveen has wide variety of Retrievable packers that suits different well conditions and operating parameters.

Types of Retrievable Packers:

Hydraulic Set

Wireline Set

Mechanical set

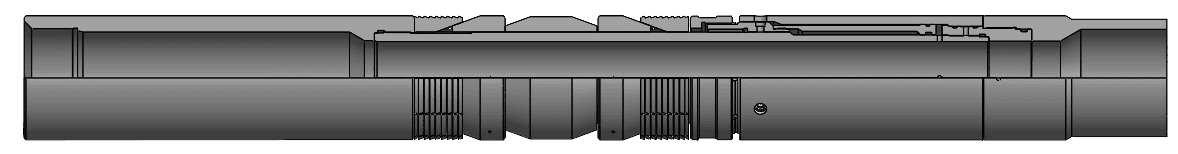

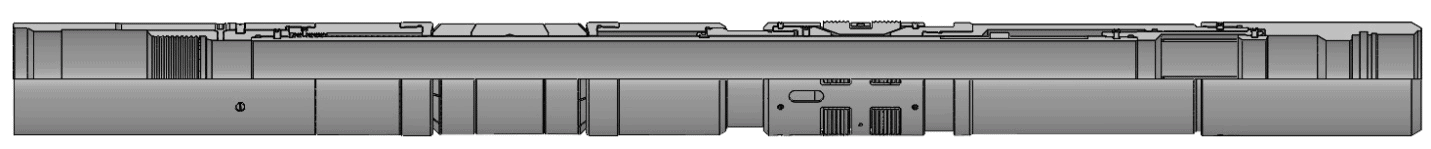

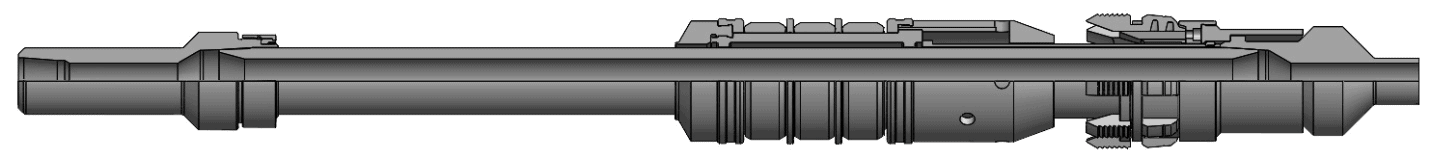

The PARVEEN MODEL RHP-DB Retrievable Packer delivers high performance with simplicity of design and desirable economics. The dual bore packer allows for a large ID through the packer by sealing in an upper seal bore. No tubing rotation required to fully set the packer. It has one-piece, self energizing packing element and features bidirectional slips below the packing element for maximum protection from debris fouling. This location protects the slips from being lost during retrieval or milling. A retrieving tool is required to retrieve these packers. PARVEEN Packers are designed for differential pressures up to 7,500 PSI.

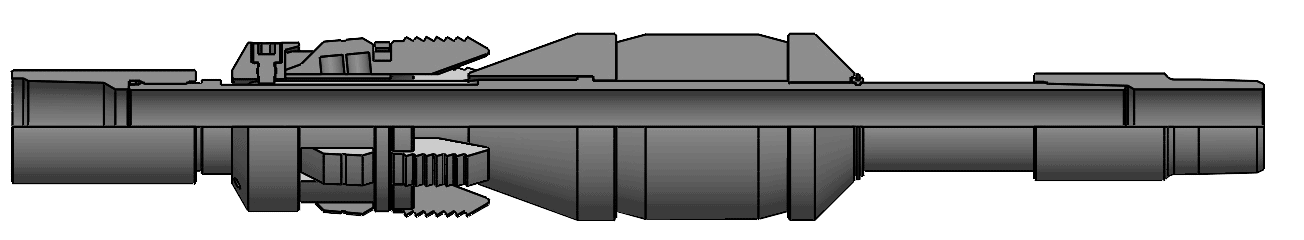

MODEL RHP-DB RETRIEVABLE PACKER

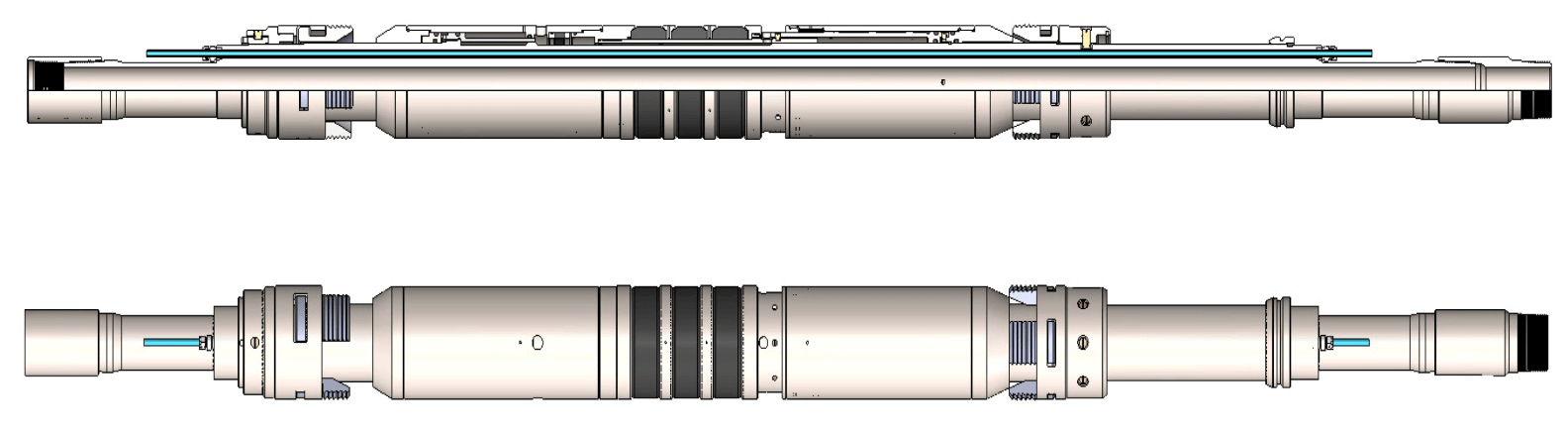

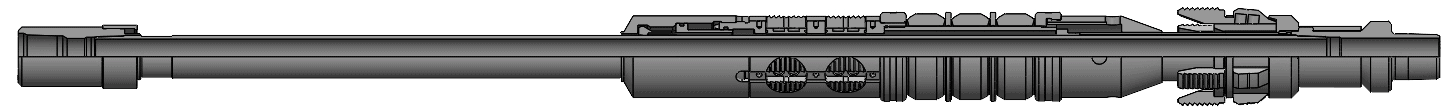

The PARVEEN MODEL RHP-SPR Packer is a hydraulic set single-string retrievable packer and may be used in virtually any production application. Tubing pump pressure is used to set the packer and the setting force is locked into the packer by a body lock ring. A large internal by-pass reduces swabbing when running and retrieving. The by-pass closes when the packer is set, and opens during the releasing process to allow pressure equalization. Shear screws are used to control the packer release. The shear release value is adjustable by adding or removing screws from the shear housing or by use of steel screws. PARVEEN Packers are designed for differential pressures up to 10,000 PSI.

RHP-SPR RETRIEVABLE PACKER

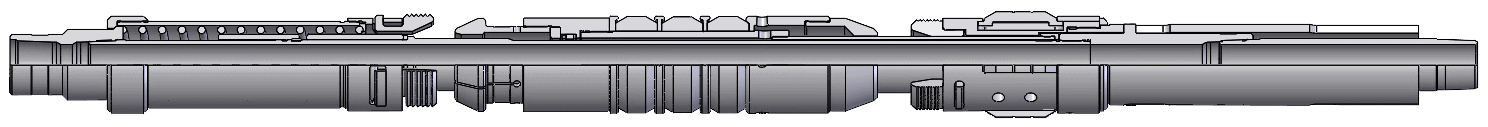

PARVEEN Model ERD Retrievable Hydraulic Seal Bore Packer is a Retrievable Packer. Hydraulically set by pressure in the tubing. It is run with Hydraulic Setting Tool & retrieving is done independently from the Tubing, using a Retrieving Tool manipulated on a work string. This packer is ideally suited for highly deviated well both onshore & offshore. Model ERD Retrievable Hydraulic Seal Bore Packer can be use in oil production wells or in water or gas injection wells. PARVEEN Packers are designed for differential pressures up to 7500 PSI.

RSBP-STR (ERD) RETRIEVABLE PACKER

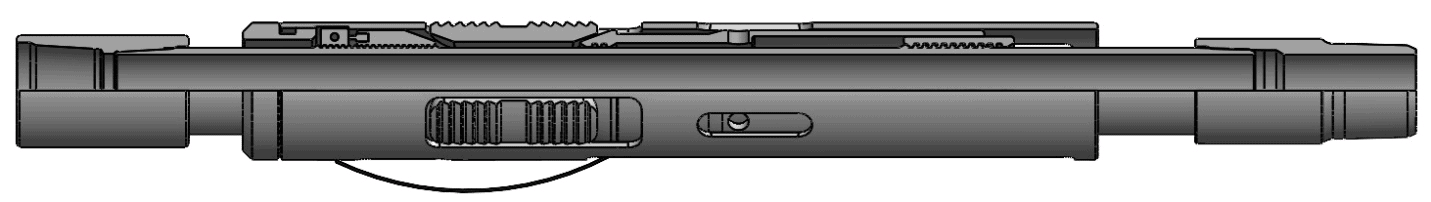

The PARVEEN MODEL RHP-SPR FEED THRU Packer is a hydraulic set retrievable packer and may be used in virtually any production application. Tubing pump pressure is used to set the packer and the setting force is locked into the packer by a body lock ring. A large internal by-pass reduces swabbing when running and retrieving. The by-pass closes when the packer is set, and opens during the releasing process to allow pressure equalization. Shear screws are used to control the packer release. The shear release value is adjustable by adding or removing screws from the shear housing or by use of steel screws.

PARVEEN FEED THRU packer can be used for smart completion, chemical injection and electrical submersible pump application. Packers are designed for differential pressures up to 7,500 PSI.

FEED THRU RETRIEVABLE PACKER

PARVEEN Hydroset II-A Packer is a hydraulic set, mechanically held dual string production packer normally run above a single string hydraulic set or wire-line set seal bore packer. Because no tubing manipulation is required to set this packer, the well head can be installed and flanged up before setting. This packer is available with short string or long string setting capabilities and a variety of tubing connections. This packer is also adaptable for electrical submersible pump applications. This packer features a sequential upper slip release system designed to release each slip individually to reduce the pull required to release the packer. The angles on the upper slips and upper slip body result in the slips releasing smoothly from the casing.

MODEL-HYDROSET-IIA DUAL STRING RETRIEVABLE PACKER

PARVEEN Model-R Single-Grip Mechanical Production Packer is a retrievable packer set by compression that isolates the annulus from the production conduit in most production, stimulation and testing operations. The field-proven design includes rocker slips and a three-element packing system that helps to ensure correct setting and pack off. These packers can be used for cementing, fracture stimulation, zone isolation and testing & production. PARVEEN Packers are designed for differential pressures up to 5000 PSI.

MODEL-R SINGLE-GRIP MECHANICAL PACKER

PARVEEN Model-R Double-Grip Mechanical Production Packer is a retrievable packer set by compression that isolates the annulus from the production conduit in most production, stimulation, and testing operations. The field-proven design includes rocker slips and a three-element packing system that helps to ensure correct setting and pack off. A hydraulic hold down controls differential pressure from below. These packers can be used for Injection, pumping, zone isolation and testing & production. PARVEEN Packers are designed for differential pressures up to 5000 PSI.

MODEL-R DOUBLE-GRIP MECHANICAL PACKER

The PARVEEN AS1-X Packer is the most versatile of the mechanically set retrievable packers and may be used in any production application. Treating, testing, injecting, pumping wells, flowing wells, deep or shallow, the AS1-X is suited for all. The packer can be left in tension or compression, depending on well conditions and the required application. A large internal by-pass reduces swabbing when running and retrieving. The by-pass closes when the packer is set and opens prior to releasing the upper slips when retrieving to allow pressure equalization. PARVEEN Packers are designed for differential pressures up to 10,000 PSI.

AS1-X MECHANICAL PACKER

The PARVEEN MODEL TST-3 Retrievable Packer is a heavy duty service packer ideally suited for all types of squeeze cementing, formation fracturing, high pressure acidizing, etc. It is a large opening compression set packer with hydraulic button-type hold down. It withstands high pressure from above or below and uses a three-element packing system, J-slot, and a drag block mechanism for easy setting. The tool features a proven three element packing system and hydraulically controlled balance sleeve designed to keep the by-pass valve closed when set. PARVEEN Packers are designed for differential pressures up to 10,000 PSI.

TST-3 MECHANICAL PACKER

The PARVEEN MODEL AD-1 Tension Packer is a retrievable, single grip tension set packer, used in water flood, oil production or treating applications. This compact, economical packer is used for shallow wells where sufficient set down weight is not available to utilize a set down packer. It is set by left hand rotation and has three release methods.

AD-1 TENSION PACKER

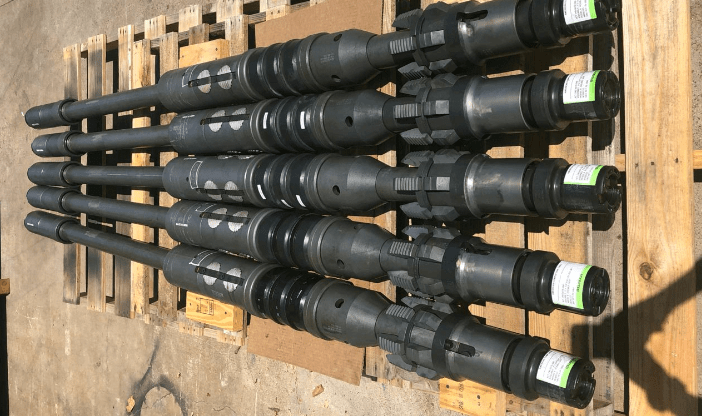

PARVEEN Tubing Anchor Catcher is a heavy duty rationally activated tool used to prevent vertical movement of the tubing string. Tubing anchor catcher act as a tubing anchor to maintain tension in the tubing string and as a tubing catcher to prevent parted pipe from falling to the bottom of the well.

Applications include: most rod pumping applications where it is important to maintain tension in the tubing.

TUBING ANCHOR CATCHER

TUBING ANCHOR CATCHER

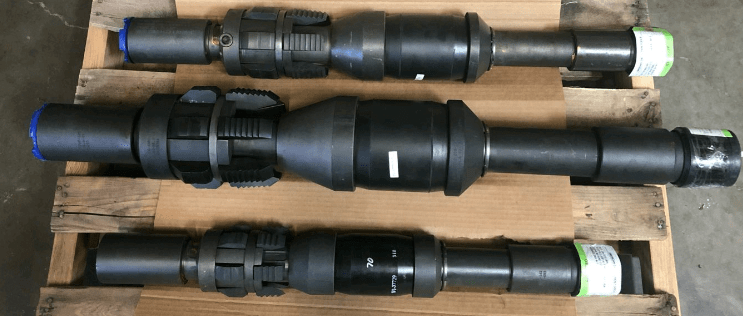

RHP-SSR Packer

RHP-SPR Packer

TST-1 Retrievable Packer