Introduction:

Parveen Industries Pvt. Ltd is a leading manufacturer and global marketer of upstream oil field equipment and products. Our oil and gas field equipment and solutions are certified by the International Inspection Agencies who verify that our oil and gas field equipment manufacturing operations comply with international industry standards. We have received API and ISO licenses for the Mumbai, Rabale and Igatpuri facilities and have also received several awards in recognition of our operational excellence.

We support various companies worldwide, working in the oil and gas, oilfield, deep-water drilling, oil and gas well, and upstream oil and gas industries. Supporting both major and independent oil producers and service companies with their oil and gas equipment, we continue to strive for excellence and remain a trusted partner within the oil and gas sector by ensuring our customers achieve significant returns on their investments.

About Parveen Industries Check Valves

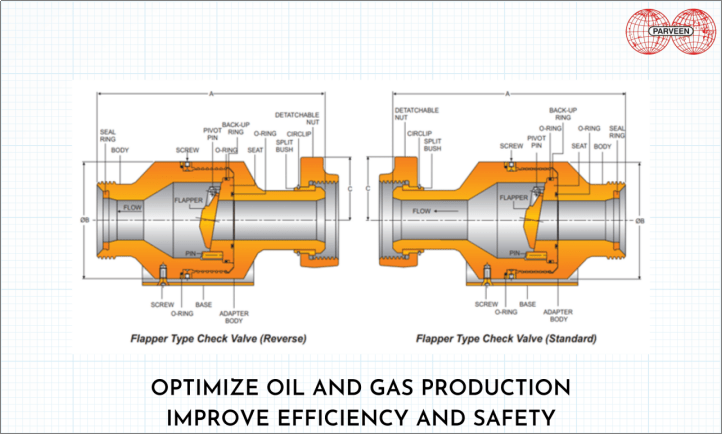

Parveen Industries Check Valves are flow control devices that permit flow in one direction but stop flow in the opposite direction. These valves are used generally in well service applications and are placed in the treating line to allow flow to the well but isolate any flow back.

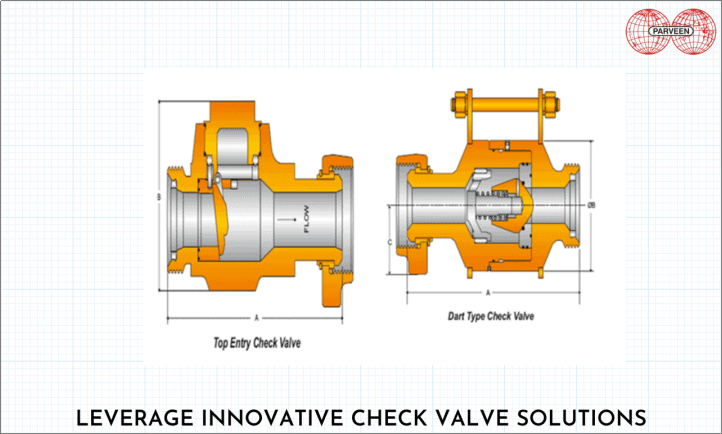

In this article, you will learn more about Parveen Industries check valve types, applications of check valves and specifications required to be mentioned while ordering the check valve.

Parveen Industries fabricates check valves for upstream oil and gas industry.

Parveen Industries Pvt. Ltd. fabricates different types of high-quality and reliable check valves and check valve unions for the upstream oil and gas industry. These check valves are specially designed to ensure that the well pressure is completely sealed off in case the wireline parts from the tool string. The check valve unions are manufactured with a steel ball. The steel ball is the component that is forced from below by the well pressure against the metal sealing area.

Parveen combines innovation, modern technology, and decades of industry experience to offer customized valve solutions for the upstream Oil and Gas industry. All the check valve products that the company offers are specially engineered, with high-performance, made with seamless technologies, and have passed a wide range of certifications like a quality standard check, quality check, and safety check.

Nowadays, more and more oil and gas processing has moved offshore. Parveen has experts to support the upstream oil and gas manufacturers with their growing needs for robust, reliable, and personalized solutions for applications on both conventional and unconventional oil reserves.

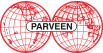

By using advanced technologies in designing and manufacturing check valve products, Parveen can help advance and optimize oil and gas production, as well as to improve efficiency and safety. The company also offers innovative check valve solutions for manufacturers using high-pressure letdown processes that are looking to inject wet steam, mine heavy bitumen resources, and separate crude product more effectively.

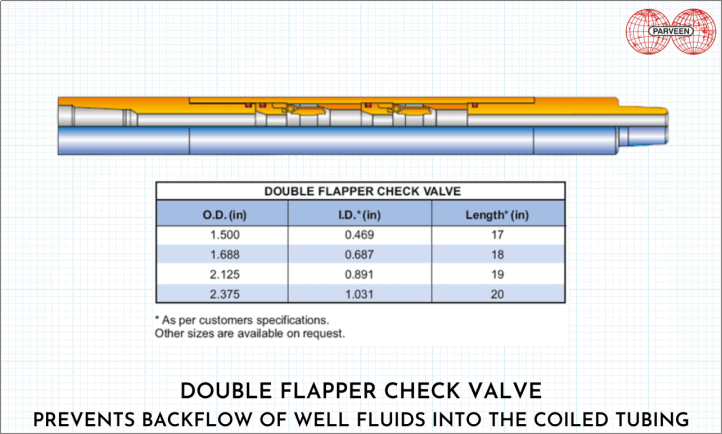

The Double Flapper Check Valve is the standard check valve used in the majority of CT operations. It is mounted close to the top of the CT string, below the connector to provide a well control barrier inside the coiled tubing against the wellbore.

Applications:

- A standard safety device used on CT operations in all oil, gas and water wells.

- Sweet and sour service (H2S).

Features:

- Allows unobstructed flow of fluids and nitrogen.

- Prevents backflow of well fluids into the coiled tubing.

- Internal full bore fluid passage for bores, darts and plugs.

- Removable flapper cartridges.

- Dual sealing flapper cartridge (low pressure teflon sealing and high-pressure metal to metal sealing).

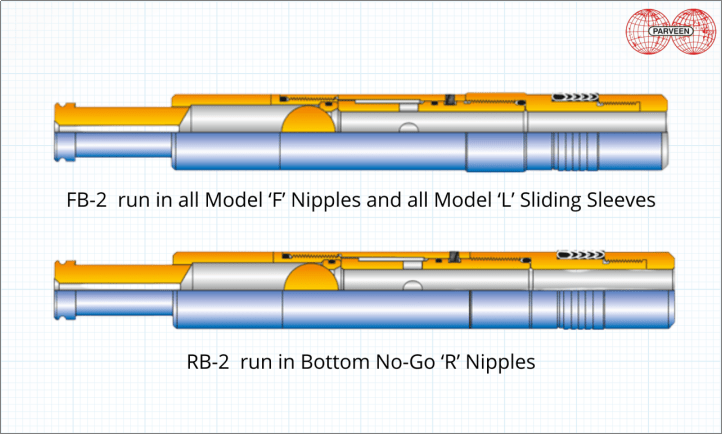

PARVEEN MODEL ‘FB-2’ AND ‘RB-2’ EQUALIZING CHECK VALVES

The PARVEEN MODEL ‘FB-2’ AND ‘RB-2’ EQUALIZING CHECK VALVES are completion equipment, without any Locking Device. These are utilized in the following Tubing Mounted Equipment:

- FB-2 run in all Model ‘F’ Nipples and all Model ‘L’ Sliding Sleeves

- RB-2 run in Bottom No-Go ‘R’ Nipples

Both models are run into a Nipple Profile and hold pressure from above only. The ‘FB-2’ model lands on the top of an ‘F’ Nipple Profile seal bore. The ‘RB2′ model seats on the Bottom No-Go Shoulder of an ‘R’ Nipple.

A ‘C-1’ Running Tool is used to run both valve assemblies.

Both models can be equalized before retrieval, by shifting open the Equalizing Mandrel Ports. Standard Pulling Tool is utilized for retrieval of these valves.

The PARVEEN ‘FB-2’ and ‘RB-2’ Equalizing Check Valves are manufactured for Standard, H2S and H2S-CO2 service.

Applications:

- Can be used as a plug to pressure test tubing.

- To set hydraulically actuated packer with the check valve positioned below the packer.

- For gas lift operations.

- To be used as a standing valve in wells which have downhole electric pumps.

Ordering information:

Please specify nipple model, seal bore size, check valve model, working pressure and temperature, percentage of H2S and CO2.

For detailed specifications please visit: https://parveenoilfield.com/ng/products/parveen-model-fb-2-and-rb-2-equalizing-check-valves/

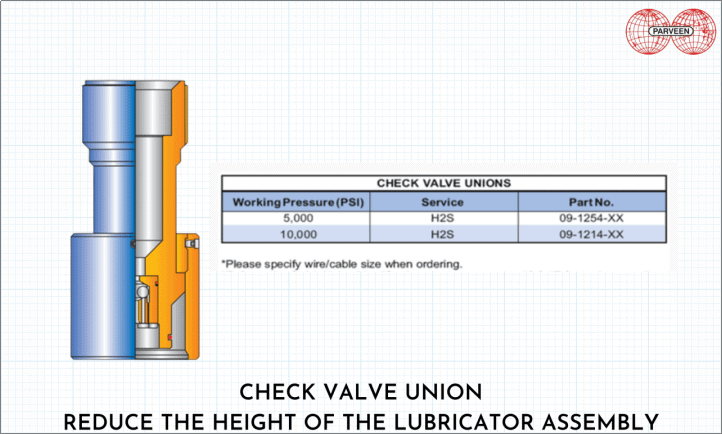

CHECK VALVE UNIONS

The CHECK VALVE UNIONS offered by Parveen Industries are engineered and fabricated as a one-piece body. These Check Valve Unions are engineered to seal off well pressure in the event of the wireline parting from the tool string.

PARVEEN Check Valve Unions are then assembled below the grease injection control head or stuffing box. To reduce the height of the lubricator assembly, an internal check valve assembly can be fitted within the grease injection control head or stuffing box as one of its integral parts. By doing this, the height of the lubricator assembly is being reduced.

Combining innovation with decades of industry-wide experience, Parveen Industries offers customized valve solutions for upstream oil and gas industry for a customized, high-performance solution for the most demanding applications including those commonly found in wellhead, separation, dehydration, compression and auxiliary systems in upstream Oil & Gas.

Contact us today for your specific requirements and site conditions.