TL;DR

- Niger Delta wells face unstable formation pressures, brackish water exposure, H2S/CO2, and difficult logistics. Your choke & kill (C&K) package must be compact, rugged, and fast to mobilize.

- Parveen’s API 16C Choke & Kill Manifold is engineered on skid-mounted modular frames for swamp barges and mat-supported sites.

- Materials, trims, and coatings are selected for corrosion resistance in humid, saline environments; iron is paired with hammer unions, quick unions, and check-valve unions to minimize leak paths and speed rig-up.

- Integration with pneumatic gate valves, adjustable chokes, and data headers supports safer operations and real-time monitoring.

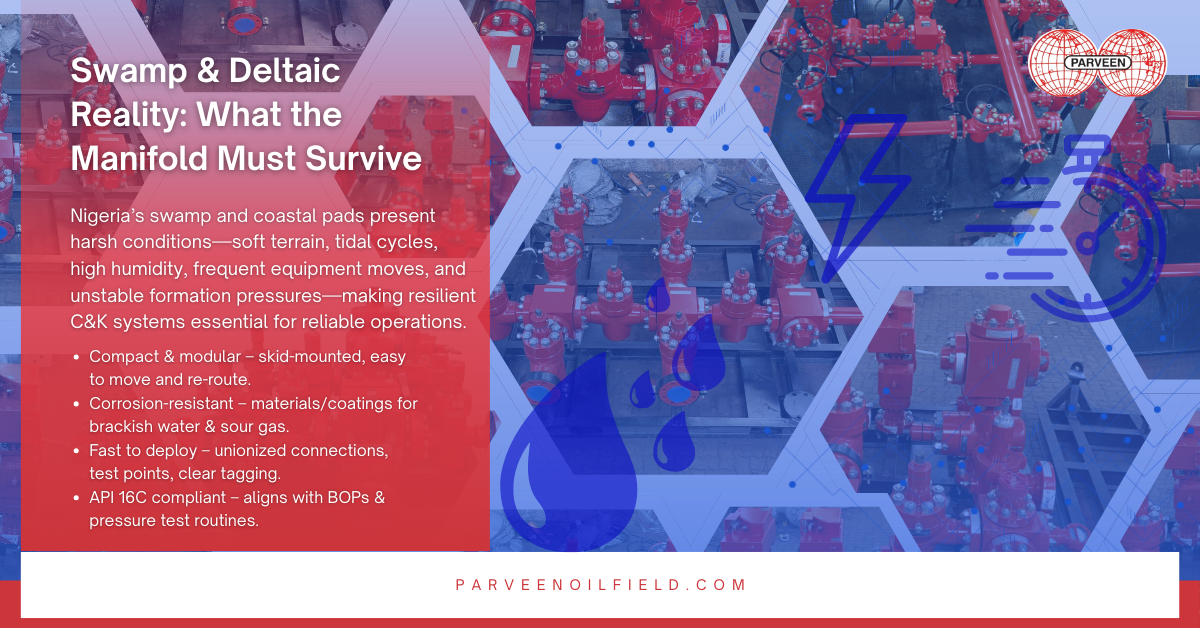

Swamp & Deltaic Reality: What the Manifold Must Survive

Nigeria’s swamp and coastal pads are unforgiving: soft ground, tidal cycles, saline humidity, and frequent equipment moves between clustered pads. Formation pressures can be unstable during spud, drilling, and flowback. That’s why operators standardize on C&K systems that are:

- Compact & modular — skid-mounted for barge or crawler transport; easy to re-route lines and add spools.

- Corrosion-resistant — suitable materials/coatings for brackish spray and H2S/CO2

- Fast to deploy — unionized connections, integrated test points, and clear tagging for quicker hook-up.

- API 16C-aligned — to complement BOP programs and pressure test routines.

Parveen’s Skid-Mounted C&K Systems for Nigeria

The heart of the package is the Choke & Kill Manifold—a configurable assembly designed to integrate with your BOP stack, trip tank circuits, and well test iron.

Built for Corrosion Resistance

- Material options & trims: selection for sour and saline service across chokes (adjustable / positive) and slab gate valves, plus pneumatic gate valves for remote actuation.

- Unionized, sealed connections: hammer unions (see also intro, 2, 3, 4, 5, 6) and quick unions reduce make-break time in humid conditions.

- Test & isolation: double-flapper check valves, blind & test flanges, and API 6A studded crosses/tees simplify proof tests and sensor integration.

Optimized for Speed & Safety

- Rapid rig-up: pre-piped skids with unitized data headers and instrument tees; standardized spools to cut hot-work.

- Pressure control options: pair the C&K with a hydraulic drilling choke (PHDC-01) for precise backpressure control and smooth circulation during kicks.

- BOP integration: compatible with Blowout Preventers and your kill line strategy; add mud valves and treating irons to streamline circulation paths.

- Well test readiness: reference layout for testing gas/condensate/oil wells to plan pressure and flow measurement points from day one.

Tie-ins & Surface Hardware That Make It Work

Swamp deployments depend on reliable tie-ins and measurement points. Parveen provides a complete API 6A surface kit for safe, fast hook-ups:

- Tubing Head, Casing Head, Tubing Head Spool, Tubing Head Adapter, Wellhead Flange Adapters

- Flanged Crosses & Tees, Flanges, Weld-Neck, Threaded, Blind

- Plug Valves, Pneumatic Gate Valve, Slab Gate Valve, Adjustable Choke

- Cementing & Circulating Hoses (threaded, welded, integral union, NPS ends)

Field Intervention: Grease Heads, Stuffing Boxes & CT

Deltaic projects often require frequent wireline/CT work under pressure. Pair the manifold with pressure-control heads designed for humid coastal service:

- Grease Injection Control Head + Grease Injection Supply System for reliable sealing during live-well work.

- Wireline Stuffing Boxes (alternate) and Lubricator & Risers to maintain slickline/wireline integrity.

- Coiled Tubing Stripper Packers and CT Quad/Combi BOP for safe underbalanced operations.

Deployment Playbook for Nigerian Coastal Pads

- Pre-engineer the skid: select choke trims, valve actuation (pneumatic), and union sizes. Include data headers for transmitters.

- Minimize hot-work: use hammer unions/quick unions and pre-tested spools; standardize with check-valve unions to shorten leak checks.

- Instrument for early warning: add taps via API 6A crosses/tees; trend choke erosion and gate-valve cycles.

- Test and document: use test flanges and the recommended test layout before first circulation.

FAQs — Choke & Kill Manifolds for Nigeria

FAQs — Choke & Kill Manifolds for Nigeria

Are Parveen C&K skids suitable for swamp barge operations?

Yes. The C&K manifold is skid-mounted with compact routing, unionized connections, and protected instrumentation—ideal for barge moves and soft pads.

What corrosion strategies are used for coastal humidity and brine?

Material and trim selection across adjustable chokes, gate valves, and spools is paired with coatings and unionized iron (hammer/quick unions) to limit corrosion and leak points.

How does it integrate with BOP stacks and kill lines?

The manifold aligns with API 16C practices and ties into your BOP choke/kill outlets, with mud valves and plug valves for isolation.

Can we add digital monitoring later?

Yes. Start with mechanical control and add transmitters via flanged tees or a unitized data header when ready.

What accessories improve uptime during interventions?

Grease control heads, stuffing boxes/alts, lubricator & risers, and CT stripper packers maintain seal integrity in humid, rainy conditions.

Resilient manifolds keep crews safe and programs on schedule—even when the weather and terrain don’t cooperate. Parveen will help you specify a compact, corrosion-resistant, API 16C-aligned C&K system that moves fast between pads and stands up to deltaic conditions.

Start here: Choke & Kill Manifold • Adjustable Choke • Pneumatic Gate Valve • Hammer Unions • API 6A Crosses/Tees