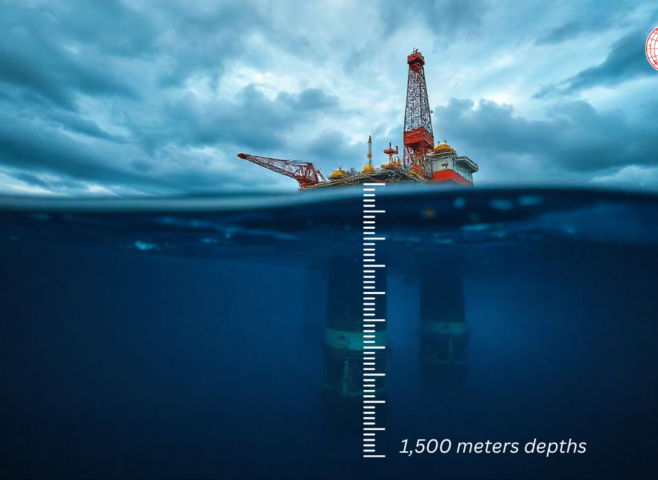

Navigating Nigeria’s Complex Subsurface Realities

Nigeria’s Niger Delta region is one of the world’s most prolific oil-producing basins—but it presents formidable completion challenges. Operators must manage complex geology, unconsolidated formations, and high annular pressures, all within swamp and deltaic environments. This terrain demands equipment that can deliver safety, precision, and integrity.

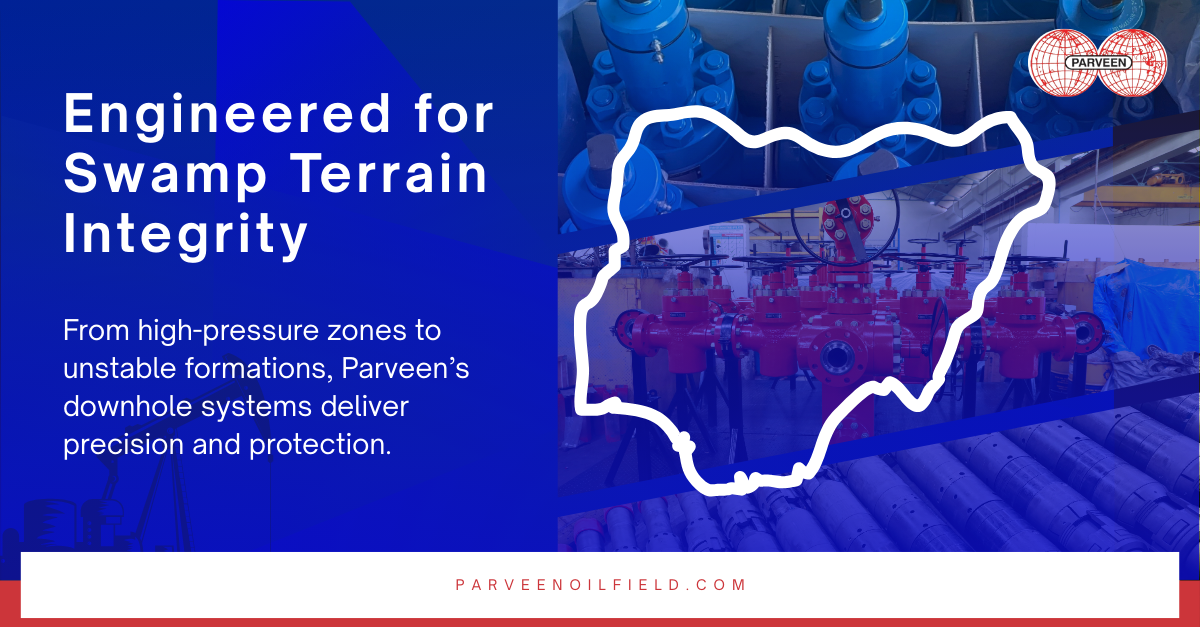

Why Safe Well Completions Matter in Swamp Terrains

In Nigeria’s onshore and shallow water assets, the risks of wellbore instability, annular flow, sand ingress, and pressure communication are high. Completion strategies must ensure zonal isolation, enable long-term production reliability, and minimize HSE risks.

Smart completions, mechanical integrity, and annular control tools are not luxuries here—they are survival mechanisms. That’s where Parveen Industries brings value through its field-proven engineering and downhole completion equipment portfolio.

Engineered Solutions for Nigerian Oilfields

Engineered Solutions for Nigerian Oilfields

Parveen’s production packer systems are designed for high-variability formations with a focus on anchoring integrity, pressure sealing, and retrievability. With equipment like chemical injection valve and flow control equipment, flow assurance and zonal control are maintained even under fluctuating production regimes.

Our hydraulic gate valves and wellhead xmas tree systems meet critical standards for safety and durability, crucial for swamp operations where access, corrosion, and pressure drops are everyday concerns.

From Swamp Floor to Surface Safety

The wellhead and surface completion infrastructure plays a pivotal role in ensuring safe operations. Our wellhead parts and unitized wellheads are fully customizable to handle casing size variations, pressure ratings, and environmental loads.

These systems are further supported by mud gate valves and adjustable choke designs, suited for high-frequency operations and field-service ease.

Specialized Equipment for Completion Success

Parveen also supplies production testing equipment for accurate flowback and well productivity evaluations—a critical factor in decision-making for fractured deltaic formations.

Downhole sand control is managed through cement retainers, gravel pack equipment, and wellbore cleaning tools like bridge plug and drill collars, which ensure the completion string operates in a debris-free and stable environment.

Driving Energy Security with Safety and Scalability

Nigeria’s goal of increasing crude output while maintaining HSE performance depends on reliable partners with proven solutions. Parveen Industries is proud to support Nigerian operators with robust, field-tested, and API-compliant systems built for swamp terrain challenges.

As the global energy map evolves, upstream reliability in geologically sensitive regions like the Niger Delta is critical. Through localized understanding, precision equipment, and scalable solutions, Parveen enables safer, smarter completions—from spud to production.