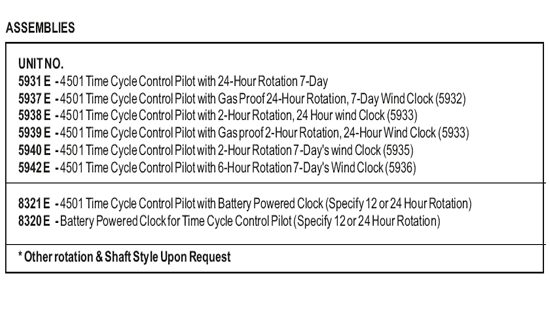

A Time Cycle Controller is recommended for any application whereit is desired to automatically open and close a valve in accordance with a predetermined time schedule. It is normally used as a time cyclecontroller on the gas injection line of an intermitting installation or as a controller on the tubing for “stop clocking” service.

The T.C.C. consist of a clock with cast aluminum wheel holding timing clips and two 3 way valves. One of the 3 way valves is operated by a trigger while the other is activated by a composition diaphragm. Operating medium is taken from the up stream gas line or from the well casing and differed through filter (1) The Pressure is then reduced by the high pressure regulator (2) to about 75 psi and further reduced to 20 psi by the low pressure regulator (3).

Assume that timing clip (9) is moved out of the path of the trigger, as shown in Figure 1. When the point of the trigger (6) falls into the slot left by the displaced clip, the other end of the trigger exerts a force on the leaf spring (8) This in turn allows the primary 3-way valve (5) to open the supply port (4) and close the exhaust port (7). The supply gas then flows through the primary 3-way valve, loading the diaphragm (14) of the secondary 3-way valve. The force exerted on this diaphragm closes the exhaust valve (13) and opens the supply valve (12) to load the diaphragm of the motor valve (16).

As the timing wheel turns counterclockwise, the timing clips bump the trigger (6) forcing the trigger to relieve its pressure on leaf spring (8). This allows the 3-way valve (5) to close supply port (4) and open exhaust port (7), bleeding pressure off chamber above diaphragm (14) The operating medium then forces supply valve (12) to close, opening exhaust valve (13). Pressure in the main diaphragm will then bleed out exhaust port (15) and valve (16) will close.