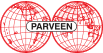

Schematic 1- The single string Gas Lift completion for intermittent lift applications utilizes a standing valve near the bottom of the tubing to prevent Gas pressure surges against the reservoir during cyclic operations. A single zone continuous lift installation would not require a standing valve but otherwise it will be identical. In either application Conventional or Side Pocket Mandrel can be used. Side Pocket Mandrels are designed to provide the facility of removing and replacing Gas Lift Valves without removing the tubing. These service operations are performed either by using wireline, through – flow line (TFL) or coiled tubing methods depending on the completion configuration. Wire line installations are more economical for servicing wells with vertical access, especially remote, offshore or other hard – to – reach locations, since wireline units are light and portable. TFL and coil tubing service methods can provide production maintenance for wells that require tubing loops, such as ocean floor completions, highly deviated wells, extremely deep wells and any well where there is no straight or vertical access for wireline service.

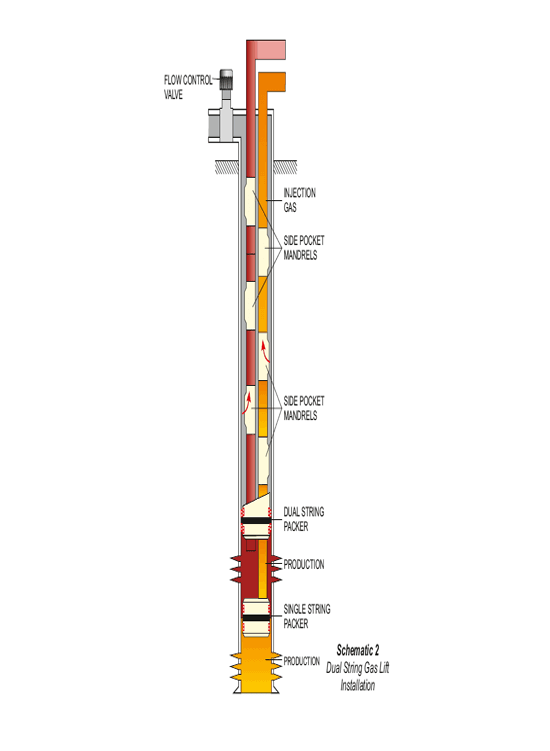

Schematic 2 – This illustrates dual-string installations where Gas Lift Valves lift fluids from two zones using gas from a common annulus. An installation can be designed, with proper well information, to produce and carry both zones to depletion. The conditions affecting dual string design are casing size, distance between zones, well bore deviation, continuous or intermittent lift and operator’s preference. Gas lift valves should be of proportional response or production pressure operated if the operation has to be trouble free.