CONSTRUCTION FEATURES (MATERIAL)

It consist of two tool joints and one central part. The steel used in the manufacture of the tool joints is a AISI-4145H mod. high purity steel, fully heat treated to 285-310 Brinell hardness and 40 ft x Ib minimum IZOD impact strength. All other physical properties conform with API standard 7 latest revised edition. The central part is made from a solid bar of modified AISI – 1340 steel, fully heat treated. The tool joints are attached by welding.

STRESS RELIEF GROOVES & CONNECTIONS FEATURES

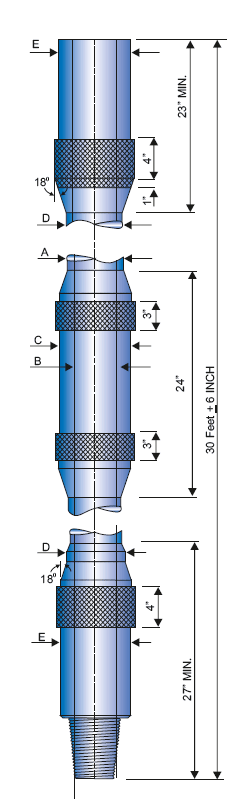

- PARVEEN long stress relief grooves on box ends are standard on 4.1/2” IF, 4” IF & 3.1/2 IF Connections.

- API stress relief grooves on pin ends are standard on 4.1/2” IF, 4” IF & 3.1/2” IF Connections.

- Thread roots are cold worked on all sizes.

- All conne

HARDBANDING

To optimize wear resistance hard banding is standard on pin and box connections and central upset. The heavy duty hard metal is sintered granular tungsten carbide 10/20 mesh or 20/45 mesh (fine particles). The hard banding is deposited by an automatic machine after pre-heating the pipe and is followed by stress relieving. Standard pads

- One 4” wear pad on both pin and box end. Plus one 1” pad on taper section of box;

- Two 3” wear pads on central upsets;The hardbanding is completely flush on both tool joints and 4/32” oversize on the central upset (fully flush on request).

On inquires and orders please specify:

- Nominal size

- Range

- API stress relief grooves, if needed

- Internal Coating, if needed.

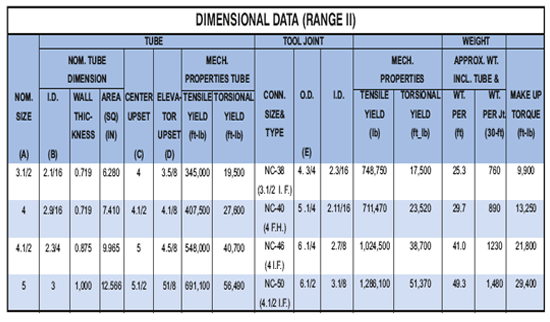

DIMENSIONAL DATA (RANGE II)