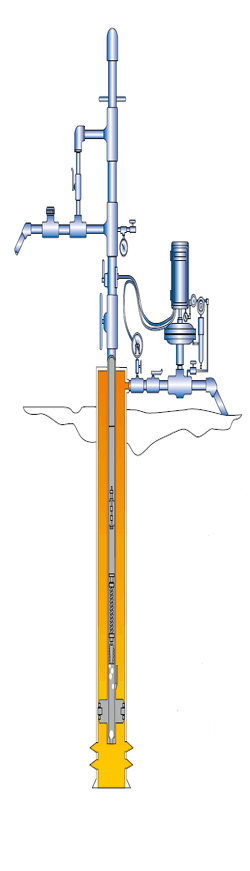

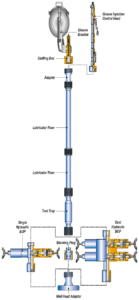

PARVEEN Plunger Lift Systems provide operators with low installation and operating cost for producing oil and gas wells. These are designed to unload excess fluids from a gas well or to increase production on an oil well. Plungers are designed as a solid interface between the fluid column and the lifting gas. There are a large number of surface arrangements being used successfully today to control fluid lifting performance of the installation. These range from basic time cycle control to more complex electronic control methods that respond to changing downhole and injection gas supply conditions, reducing the need for frequent inspection to maintain optimum installation operation. Plunger Lift is ideal for: (1) improving the efficiency of intermittent gas lift (2) removing liquid from gas wells (3) producing high GOR wells/solution gas drive reservoirs and (4) preventing paraffin and/or scale buildup.

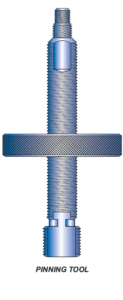

One of the main objectives of a Plunger Lift installation on a gas producing well is to keep the area in the immediate vicinity of the wellbore as dry as possible. To perform this function when the formation is producing liquids along with the gas, the gas flow must be of sufficient velocity to deliver all liquids to the surface as they enter the wellbore. The heart of the installation is the plunger itself, of which PARVEEN offers several designs to meet different well requirements. The plunger is installed in the tubing string and becomes an interface between the fluid and the gases as it travels to the surface to expel accumulated fluid. The plunger movement is the result of a cyclic operation that creates a differential across the plunger. This is normally accomplished by opening and closing a motor valve with a time cycle controller such as the auto controller.