High-pressure oilfields in the United States, particularly in regions like the Permian Basin, Eagle Ford, and Bakken, pose significant operational challenges. Maintaining well integrity and ensuring safe production under extreme pressures requires robust, API-certified wellhead equipment that can withstand harsh conditions. With increasing regulatory scrutiny from organizations like the Bureau of Safety and Environmental Enforcement (BSEE) and the Environmental Protection Agency (EPA), operators must adopt advanced wellhead solutions to mitigate risks and enhance safety.

The Challenges of High-Pressure Oilfields in the USA

USA oilfields are evolving, with operators drilling deeper and encountering higher pressures and temperatures than ever before. Some of the key challenges include:

- Well integrity risks due to extreme pressures that can lead to blowouts if not managed properly.

- Equipment fatigue and failure caused by high-stress conditions.

- Regulatory compliance with stringent safety and environmental regulations.

- Erosion and corrosion from aggressive fluids, gas, and sand production.

- Pressure control issues requiring precision engineering to prevent leaks and maintain well stability.

The Role of Advanced Wellhead Equipment

Wellhead systems serve as the primary barrier between high-pressure reservoirs and surface operations. Using high-performance wellhead and X-Mas tree systems ensures that oil and gas wells remain safe and productive.

Key Features of Advanced Wellhead Equipment for High-Pressure Wells

- High-Pressure Sealing Technology

- Advanced metal-to-metal seals ensure leak-proof connections, even under extreme pressure.

- Secondary and tertiary sealing mechanisms provide additional protection against blowouts.

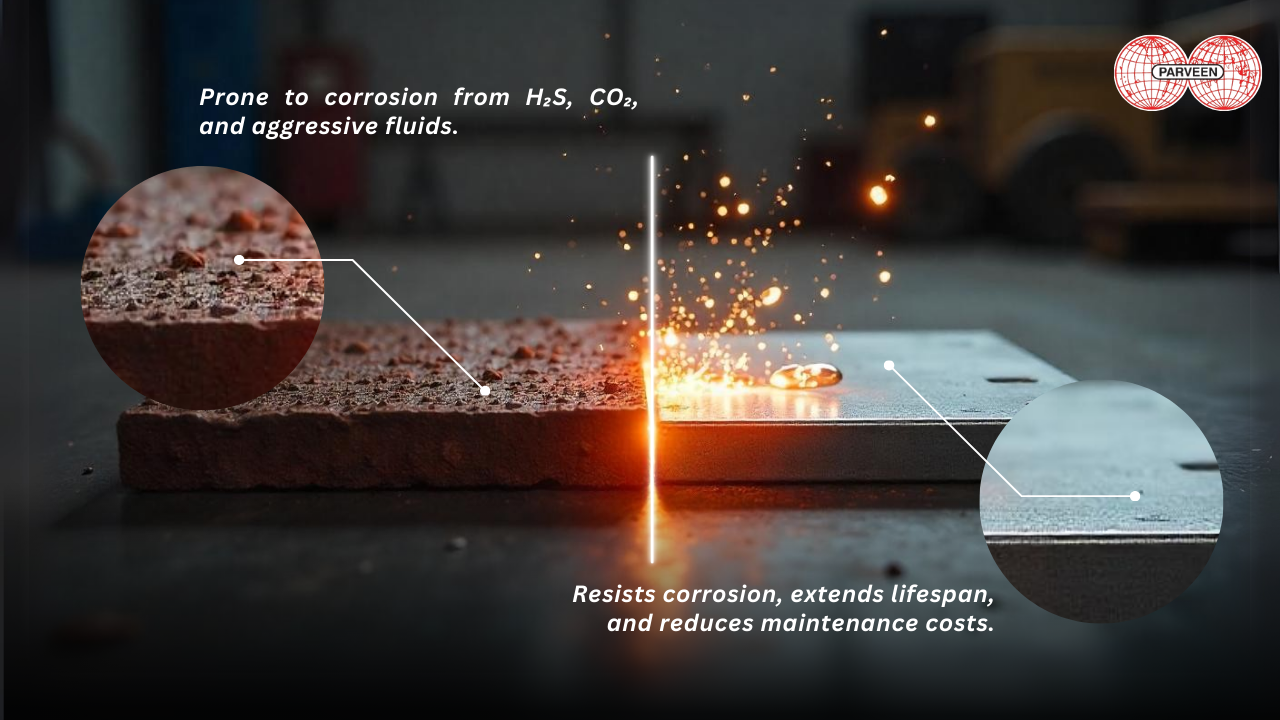

- Corrosion-Resistant Materials

- Stainless steel and alloy coatings resist corrosion from sour gas (H2S), CO2, and other aggressive fluids.

- Longer equipment lifespan reduces maintenance costs and downtime.

- API and ISO Certification

- Compliance with API 6A standards ensures reliability in high-pressure environments.

- Operators can meet strict BSEE and EPA safety regulations with certified equipment.

- Pressure Control and Flow Optimization

- Integrated choke and gate valves provide precise flow control, preventing pressure surges.

- Adjustable production chokes allow operators to optimize flow rates safely.

- Enhanced Structural Integrity

- Forged wellhead components offer superior strength compared to cast counterparts.

- Multi-bowl wellhead systems enable efficient pressure containment while minimizing risks.

How Parveen Industries’ Wellhead Solutions Improve Safety in USA Oilfields

Parveen Industries delivers cutting-edge wellhead and X-Mas tree systems designed for the toughest oilfield environments. Our solutions help USA operators:

- Maintain well integrity even under extreme pressure and temperature conditions.

- Enhance operational safety by preventing leaks and blowouts.

- Increase production efficiency with optimized flow control mechanisms.

- Achieve regulatory compliance with API-certified, BSEE-approved equipment.

Our Featured Wellhead Solutions

- API 6A Wellhead Systems – Designed for high-pressure, high-temperature (HPHT) applications.

- X-Mas Trees – Providing reliable pressure and flow control.

- Gate Valves and Choke Valves – Ensuring leak-proof, precision flow management.

- As high-pressure drilling continues to expand in the USA, ensuring well integrity and safety remains a top priority. Investing in advanced wellhead equipment from Parveen Industries equips operators with the reliability, performance, and regulatory compliance needed to maximize production while safeguarding personnel and assets.

For high-performance wellhead solutions tailored to your USA oilfield operations, contact Parveen Industries today!